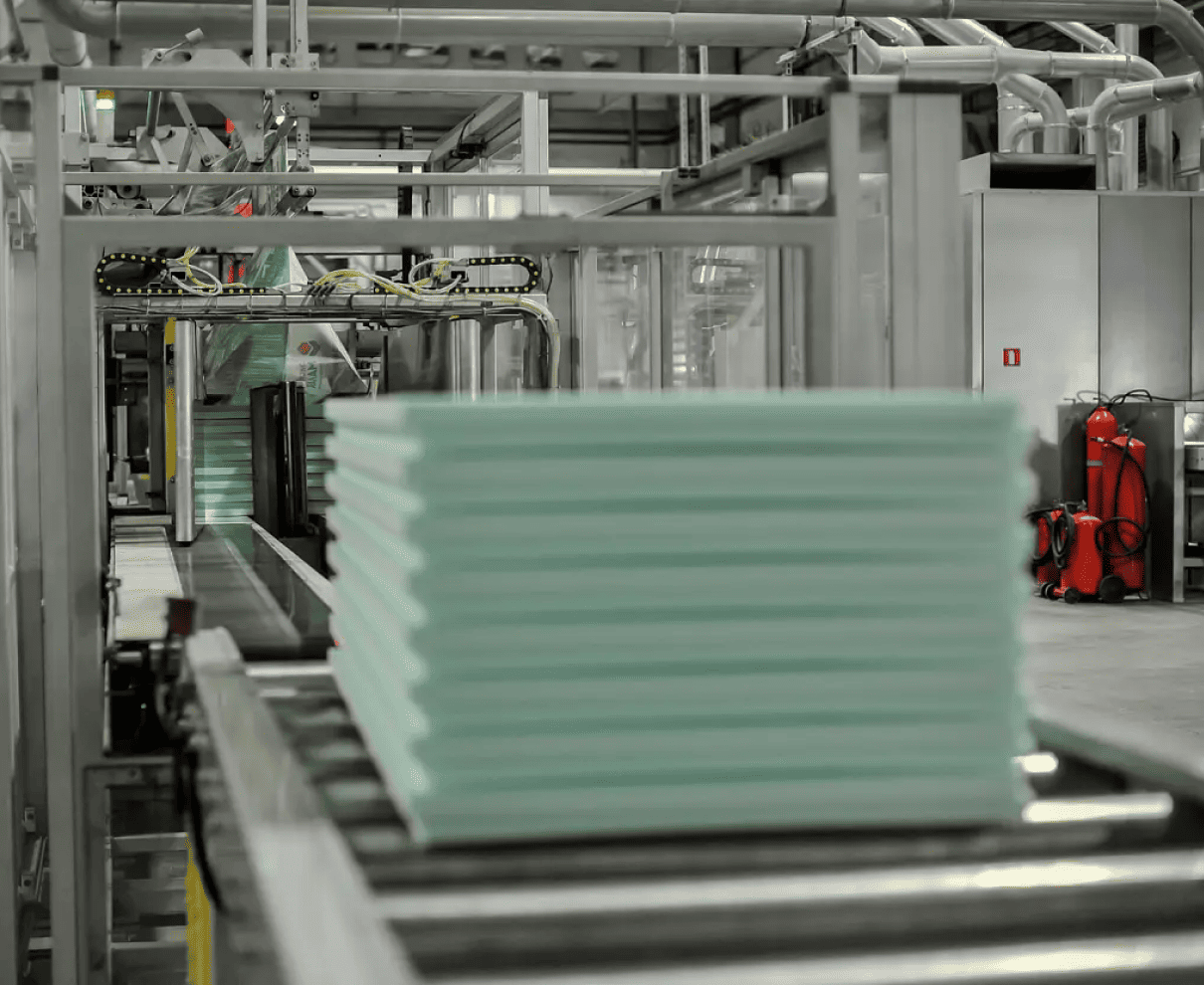

Equipment for the

production of

extruded polystyrene

foam (XPS)

Our company worked and collaborated

with the world's leading manufacturers

of equipment for the production of insulation

from extruded polystyrene foam.

We worked on European and Asian production lines,

and modernized these lines.

with the world's leading manufacturers

of equipment for the production of insulation

from extruded polystyrene foam.

We worked on European and Asian production lines,

and modernized these lines.

Main

—

Equipment

We have extensive experience in operation and know the features of equipment from different manufacturers.

We can help you choose the optimal production line in terms of price-quality ratio,

to avoid additional costs due to incorrectly selected equipment and an incorrectly equipped production line.

And, we can also help modernize the existing production according to your requirements and goals,

we have extensive experience working with different production lines and in different countries and we can help you improve the technology and make production more cost-effective, less energy-intensive and more environmentally friendly.

Our experience in this industry allows us to independently develop and manufacture additional equipment for XPS production lines.

Additional foaming device. This device is designed to reduce the density of the manufactured products by additional

foaming of the insulation. The insulation tape, passing through the device, experiences mechanical and temperature effects, due to which the gas molecules inside the insulation expand and additional foaming of the material occurs. This device allows you to reduce the density of the manufactured products without losing quality by 10-25%! Accordingly, the Customer's company will receive additional profit.

foaming of the insulation. The insulation tape, passing through the device, experiences mechanical and temperature effects, due to which the gas molecules inside the insulation expand and additional foaming of the material occurs. This device allows you to reduce the density of the manufactured products without losing quality by 10-25%! Accordingly, the Customer's company will receive additional profit.

Gas preparation device for better absorption in the polymer. This device works to control the temperature of the foaming agents that are fed to the first extruder. The presence of this device allows you to increase the percentage of cheaper gases used, and accordingly reduce the amount of expensive gases.

As a result, the cost of manufactured products will be lower.

Device for continuous monitoring of the thickness of the insulation. It is no secret that the human factor affects

the increase in the cost of manufactured products. If the production line operator has not calibrated the thickness

of the product accurately, for example, instead of 50 mm he installed 52-53 mm, the cost of production will increase by 4-6%. Accordingly, the company's profit will be lower. Our device for monitoring the thickness of manufactured products, measures the thickness of the product at three points in real time and in case of a change in thickness gives a signal so that the operator can make an adjustment.

the increase in the cost of manufactured products. If the production line operator has not calibrated the thickness

of the product accurately, for example, instead of 50 mm he installed 52-53 mm, the cost of production will increase by 4-6%. Accordingly, the company's profit will be lower. Our device for monitoring the thickness of manufactured products, measures the thickness of the product at three points in real time and in case of a change in thickness gives a signal so that the operator can make an adjustment.

Our company produces tanks for storing and pumping foaming liquids, additional devices for monitoring and warning about possible malfunctions, on-board recorders for monitoring all parameters of the production line with continuous recording and the ability to analyze the data received. As well as other devices designed to improve, reduce the cost, optimize and make the production process safer.

Our equipment is aimed at reducing production costs, reducing the cost of finished products, automating the production process and quality control. Here are some examples:

Send a request

and our manager will tell you more about the stages

of process optimization in your production

of process optimization in your production